Articles in this section

Stock Management in Vtiger CRM

Feature Availability

Vtiger Editions: One Pilot | One Growth | One Professional | One Enterprise

Introduction

Stock management is a critical function for any business that sells, distributes, or stores products. It involves monitoring, controlling, and optimizing inventory levels to ensure that items are available when needed—without holding excessive Stock that leads to unnecessary costs or risks such as damage or obsolescence.

Effective stock management relies on strategic practices such as forecasting, inventory control, stock rotation, and periodic stock counts. In Vtiger CRM, Stock Management helps businesses maintain accurate stock levels, streamline operations, and make informed decisions using automated, rule-based inventory updates.

Stock Management in Vtiger CRM

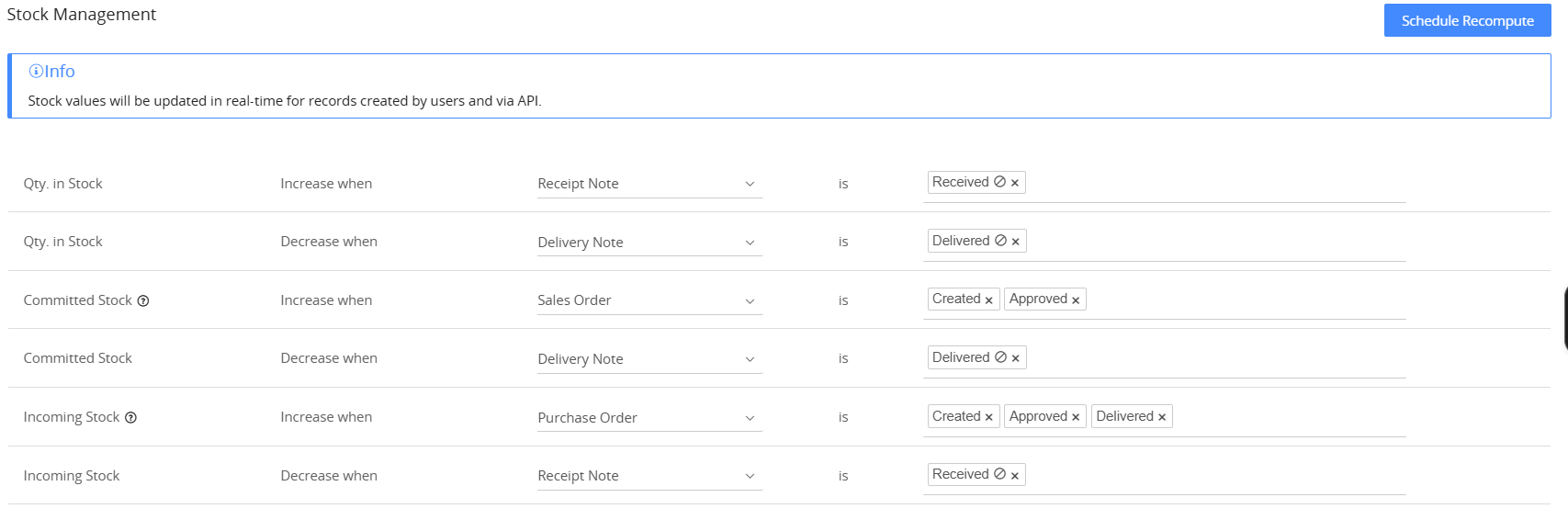

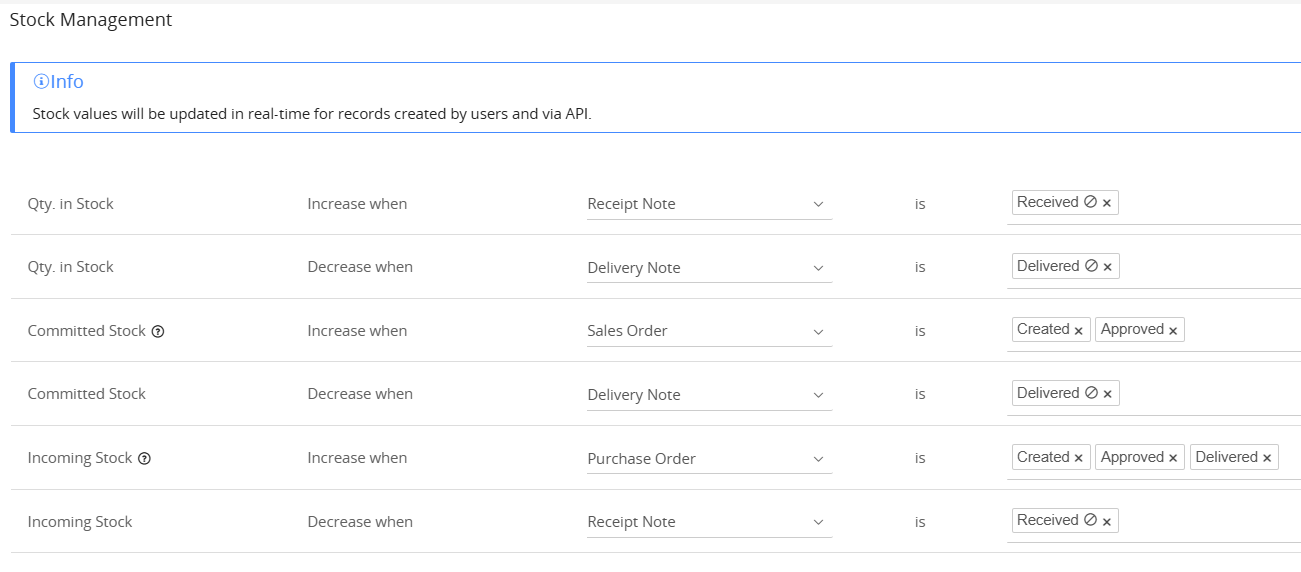

Vtiger CRM utilizes picklist-driven rules to adjust stock quantities, eliminating the need for custom workflows. The Stock Management settings page enables administrators to configure when and how stock updates occur, based on the inventory module statuses. This centralization allows businesses to manage inventory, purchase operations, and sales commitments with greater accuracy, reducing the risk of stockouts or overstocking.

Stock Management Fields in Product Records

The Stock Management settings control three key fields for each product:

- Available Stock: The quantity of items available for sale is obtained by subtracting committed Stock from total Stock.

- Committed Stock: Items reserved for open sales orders.

- Incoming Stock: Items ordered from vendors that have not yet been received.

Key Features

The key features of Vtiger's Stock Management are:

- Automated Stock Updates: Automatically increases or decreases stock quantities based on related sales and purchase records.

- Centralized Inventory Tracking: Consolidates inventory data across products, orders, and warehouse activities.

- Configurable Stock Rules: Allows administrators to configure conditions under which Stock increases, decreases, or remains unchanged.

- Real-Time Stock Visibility: Displays available, committed, and incoming Stock directly at the product record level.

- Scheduled Recompute: Automatically recalculates stock values based on outstanding orders.

- Integration with Inventory Modules: Works seamlessly with Sales Orders, Purchase Orders, Invoices, Delivery Notes, and Receipt Notes.

Benefits

The benefits of Stock Management in Vtiger are:

- Improve Order Fulfillment Accuracy

- Ensure Stock is available to fulfill orders on time and reduce the risk of stockouts.

- Optimize Inventory Costs

- Avoid overstocking and reduce capital tied up in unused inventory.

- Enhance Decision-Making

- Use real-time stock data to adjust reorder points, forecast demand, and plan procurement strategies.

- Streamline Operations

- Integrate inventory updates across sales, purchasing, and warehousing for greater operational efficiency.

- Ensure Data Accuracy

- Maintain consistent and reliable stock values without manual updates or workflow dependencies.

- Gain Complete Inventory Insights

- Track available, incoming, and committed stock in a single platform.

In this article, you will learn about:

- Stock Management in Vtiger

- Configuring the Stock Management settings page

- Scheduling Recomputation of Stocks

- Troubleshooting Tips

Key Terminology

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Configuring Stock Management

As an Admin user, you can configure the Stock Management settings on the Vtiger CRM settings page. To use this feature, install the Inventory Add-on from the Add-ons section.

Follow these steps to configure Stock Management:

- Log in to your CRM account.

- Go to the Main Menu.

- Click Settings.

- Click Inventory > Stock Management under the Configuration section. The Stock Management page opens. You can see the different fields related to the product stock.

- Enter or select information for the following:

- Qty. in Stock

- Increases when you:

- Select the required inventory record from the drop-down. The inventory module record may be a Purchase Order or a Receipt Note.

- Select all the required statuses of the inventory module record from the drop-down. For example, you set the Purchase Order as Delivered as the increasing status.

- Increases when Purchase Order = Delivered.

- Increases when Receipt Note = Received.

- Decreases when you:

- Select the required inventory record from the drop-down. Inventory module records may be Sales Orders, Invoices, or Delivery Notes.

- Select all the required statuses of the inventory module record from the drop-down. For example, you set the Delivery Note status to Dispatched/Delivered as the decreasing status.

- Decreases when Sales Order = Delivered.

- Decreases when Invoice = Delivered.

- Decreases when Delivery Note = Delivered.

- Increases when you:

- Committed Stock

- Increases when you:

- Select the required inventory module record from the drop-down. The inventory module record here can only be a Sales Order.

- Select all the required open statuses of the inventory module record from the drop-down. For example, you set the Sales Order to an approved status.

- Committed Stock increases when Sales Order = Open / Confirmed.

- Decreases when you:

- Select the required inventory record from the drop-down. The inventory module record can be a Sales Order or a Delivery Note.

- Select all the required closed statuses of the inventory module record from the drop-down. For example, you set Delivery Note is Delivered as the decreasing status.

- Committed Stock decreases when Sales Order = Delivered.

- Committed Stock decreases when Delivery Note = Delivered.

- Increases when you:

- Incoming Stock

- Increases when you:

- Select the required inventory record from the drop-down. The inventory module record here can only be a Purchase Order.

- Select all the required open statuses of the inventory record from the drop-down. For example, you set the Purchase Order as Ordered as the increasing status.

- Incoming Stock increases when Purchase Order = Approved.

- Decreases when you:

- Select the required inventory record from the drop-down. The inventory module record can be a Purchase Order or a Receipt Note.

- Select all the required closed statuses of the inventory record from the drop-down. For example, you set the Receipt Note as Received as the decreasing status.

- Incoming Stock decreases when Purchase Order = Closed.

- Incoming Stock decreases when Receipt Note = Received.

- Increases when you:

- Qty. in Stock

Note: If you don't want to update your stock using the Stock Management configuration in Vtiger CRM, you can choose the Never option from the drop-down instead of creating an Inventory module record. This will prevent any updates to your stock levels through the Stock Management feature.

Use Case

ABC Electronics sells home appliances, including refrigerators, microwaves, and washing machines. They use Vtiger CRM to track stock movement across sales and purchase activities.

The Admin configures Stock Management as follows (based on the image):

- Qty in Stock — Increases when the Receipt Note is Received.

- Qty in Stock — Decreases when the Delivery Note is Delivered.

- Committed Stock — Increases when the Sales Order is Created or Approved.

- Committed Stock — Decreases when the Delivery Note is Delivered.

- Incoming Stock — Increases when the Purchase Order is Created, Approved, or Delivered.

- Incoming Stock — Decreases when the Receipt Note is Received.

Recomputation of Stock

Committed Stock, Incoming Stock, and Available Stock for all products are recomputed based on outstanding sales and purchase orders. You can recompute the value using the Schedule Recompute button in the Stock Management settings page or using the Recompute Stock Values option in a product record.

Recomputing Stock Values(levels) of a Product

Follow these steps to recompute the stock values of a product:

- Log in to your CRM account.

- Click the Main Menu.

- Click Inventory > Products. The Products module List View opens.

- Hover over and click the required product. The Summary View of the record opens.

- Click the More icon in the top right corner.

- Click Recompute Stock Values.

The system recalculates all inventory items, including those added and reduced as specified in the purchase and sales orders imported into the CRM.

Note: The Committed and Incoming stocks for a product and its sub-products will be updated during recomputation.

Scheduling the Recomputation of Stocks

When you schedule the recompute of stocks via the recompute Cron, it will run at 11 PM in the account owner's timezone.

Follow these steps to schedule a stock recompute:

- Log in to your CRM account.

- Go to the Main Menu.

- Click Inventory > Stock Management under the Configuration section. The Stock Management page opens. You can see the different fields related to the product stock.

- Click Schedule Recompute.

- Note: You will see a message about the recomputation of Cron, and the system prompts you to recompute stock values from a product record if you want to recompute a specific product's stock.

- Click Schedule.

Troubleshooting Tip

If you have made frequent changes to the Stock Management settings page, recalculating a product's stock from its record may sometimes be limited. In such cases, you can always visit the Stock Management Settings page and schedule the recompute cron by clicking Schedule Recompute.Stock Management Fields Behavior

The following are the different ways the values in the stock fields are updated:

Qty in Stock

Increases when:

- New items are added through Purchase Orders or Receipt Notes.

- Positive stock adjustments are approved.

Decreases when:

- Items are sold or delivered.

- Negative stock adjustments are approved.

- Items are marked as defective and removed from usable stock.

Available Stock

Increases when:

- New stock is received and added to Total Stock.

- Reserved or committed quantities are released/canceled.

Decreases when:

- Stock is reserved for an order.

- Stock is committed to a Sales Order.

- Stock is delivered or invoiced.

- Stock is adjusted negatively or marked defective.

Reserved Stock

Increases when:

- Stock is reserved for a customer order.

Decreases when:

- The reservation is cancelled.

- The reserved stock is marked as ordered.

- Convert the reservation into a Sales Order.

Committed Stock

Increases when:

- Items are allocated to a confirmed Sales Order.

- Delivery planning begins, and stock is officially assigned.

Decreases when:

- The items are delivered to the customer.

- The Sales Order is canceled or revised.

Defective Stock

Increases when:

- Damaged or faulty units are recorded during audits.

- Customers return items and mark them as defective.

Decreases when:

- Defective units are repaired and moved back to usable stock.

- Faulty items are scrapped or removed during stock adjustments.

Incoming Stock

Increases when:

- Items are added through a Purchase Order marked as Ordered.

- Goods are expected but not yet physically received.

- Partial shipments are pending delivery from the vendor.

- A Receipt Note is created in Draft or Pending status.

Decreases when:

- Items have been fully received, and the Receipt Note has been completed.

- The Purchase Order is canceled or revised to a lower quantity.

- The vendor reduces the shipment quantity.

- Incoming items are converted into Total Stock upon receipt.

Stock Management Status Field

You do not need to consider sales and purchase orders in the Closed state when calculating Committed and Incoming stocks.

-

Here are the other options:

- Qty in stock increases

- When a purchase order is fully received or in any other custom closed status.

- When a receipt note is in Received or in any other custom closed status.

- Qty in Stock Decreases

- When a sales order is in the Fully Delivered or any other customer-closed status.

- When the delivery note is in the Delivered or any other custom closed status.

- When the invoice is in any status except Canceled.

- Committed Stock increases

- When a sales order is in New or any other open status.

- When a sales order is in Fully Delivered or any other closed status.

- When a delivery note is in Delivered or any other closed status.

- Incoming Stock increases

- When a purchase order is in New or any other open status.

- When a purchase order is in Fully Received or any other closed status.

- Incoming Stock decreases when a Received Note is in Received or any other closed status.

- Qty in stock increases